How Much Nm Torque Can You Apply By Hand?

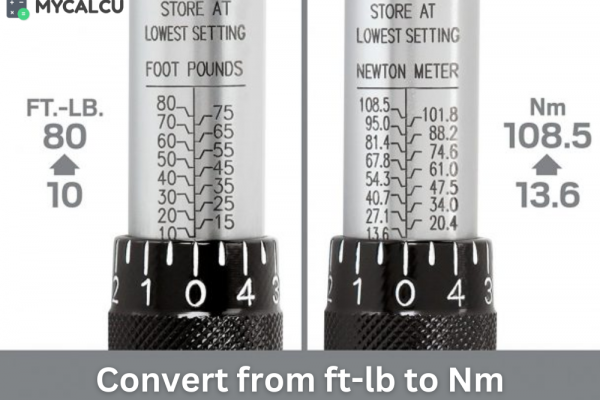

The amount of torque that a person can apply by hand can be measured in either newton meters (Nm) or pound-feet (lb/ft). These units are both used to measure the rotational force applied to any object. You can convert between both of them using the following formula.

There is no constant figure to how much torque you can apply by hand, but the average person can typically apply between 30 and 50 Nm of torque by hand. This can be converted to pound-feet using the above formula:

These numbers are simply average, and actual figures vary from person to person. For example, the torque required to loosen a bolt on a car's engine is typically 50 to 80 Nm, equivalent to 37 to 59 lb/ft. This is significantly higher than the average person can apply by hand and would require a tool such as a torque wrench.

In summary, the amount of torque that a person can apply by hand can vary significantly depending on the individual. However, it is generally considered that the average person can apply between 30 and 50 Nm, or 22.12686447 and 36.87807412 lb/ft, of torque by hand. Tasks that require higher levels of torque, such as tightening lug nuts on a car's wheels, would typically necessitate the use of a tool to produce higher torque figures.

How Many Newton Meters Is Finger-Tight?

The term "finger-tight" refers to the amount of torque that can be applied by hand without the use of tools, and it is generally considered to be a relatively low level of torque, typically in the range of 5 to 15 Newton meters (Nm). This can be converted to pound-feet (lb/ft) using the following conversion formula:

1 Nm = 0.737562149 lb/ft

Using this formula, the range of torque that is typically considered "finger-tight" can be expressed in pound-feet as follows:

These numbers are arbitrary, and they are calculated using a simple average. It may depend on the size and technique of a person and many additional factors. Some people may be able to apply more torque by finger-tightening than others, and the actual torque may also depend on the specific task at hand and the materials being worked with.

How Much Torque Is 25 Nm?

25 Nm is close to what a human can normally apply. It has a reasonable amount of torque, enough for jobs like building furniture or connecting tiny pipes. It is within the torque range that the ordinary person can apply with a wrench by hand, but it is still greater than the "finger-tight" range of 5 to 15 Nm. 25 Nm is equal to 18.43903523 lb/ft in pound-feet.

In real life, The torque necessary to release a bolt on a car's engine is normally in the range of 50 to 80 Nm, but the torque required to tighten lug nuts on a car's wheels is typically around 100 Nm. These numbers are substantially more than 25 Nm and would normally necessitate using an instrument such as a torque wrench. This can give you the scale on which 25Nm is compared to the general torque applied on different objects.

How Much Is 20 Nm Torque?

20 Nm or 14.75202819 lb/ft is a moderate amount of torque. It is close to what a human can apply on average, but it is still way higher than “finger tight” torque which is 5 to 15 Nm. Here are a few examples to give you a general estimate of how much this calculates in real life.

- Tightening a bolt on a bicycle wheel normally requires roughly 15 Nm of torque. This is less than the 20 Nm torque limit and is usually achievable by hand with a wrench.

- The torque required to tighten a bolt on a car's suspension is approximately 25 Nm. This torque level is somewhat greater than 20 Nm and may necessitate using a torque wrench or other mechanical advantage.

- The amount of torque required to remove a bolt on a lawn mower blade is roughly 30 Nm. This is far more than the 20 Nm torque limit and would normally necessitate using a torque wrench or other mechanical advantage.

How Much Torque Is Hand Tight Screwdriver?

Screwdrivers are available in a number of sizes and kinds to suit various screws. They are normally made with a handle and a shaft placed into the screw's head. The handle applies torque, or rotational force, to the shaft, which spins the screw.

The amount of torque that can be applied with a screwdriver is determined by the screwdriver's size and the type and the individual's strength, size, and technique. Because it has a longer lever arm, a bigger screwdriver with a longer handle can often apply greater torque than a smaller one. However, using too much force with a screwdriver might shred the screw's head or cause the screwdriver to slide, which can result in injury or damage.

The phrase "hand-tight" refers to the amount of torque that may be exerted with a screwdriver or other instrument by hand without the need for extra mechanical advantage. It is widely acknowledged to be a low amount of torque, often in the 5 to 15-newton meters (Nm) range, or 3.68790696 to 11.06372089 pound-feet (lb/ft). This is enough for jobs such as furniture assembly or connecting tiny pipes, but it may not be adequate for applications requiring a greater amount of torque.

In essence, a screwdriver is a tool for turning screws and fastening things together. The amount of torque that can be applied with a screwdriver is determined by the screwdriver's size and the type and the individual's strength and skill. The phrase "hand-tight" refers to the amount of torque that may be exerted by hand using a screwdriver or other instrument without the need for extra mechanical advantage and is typically regarded as a low degree of torque.

How Much Torque Is Needed To Overtighten Screws?

Overtightening screws happen as a result of applying more torque than is required to hold a screw in place. This can harm the screw and the surrounding material, and it is widely regarded as a bad technique in many situations.

The amount of torque required to overtighten a screw varies depending on the screw and its applied material. In general, the torque needed to attach a screw is less than that needed to strip or destroy the screw.

The torque required to overtighten a screw is often 20 to 30% more than the recommended torque for the individual screw and material. For example, if the recommended torque for a certain screw is 10 Nm, overtightening would be in the 12 to 15 Nm range.

It is important to note that even at low torque levels, overtightening can cause damage to the screw and the surrounding material. As a result, it is critical to follow the manufacturer's instructions for the proper degree of torque and to apply the precise amount of torque using a torque wrench or other equipment.

Torque can also be stated in pound-feet (lb/ft) and Nm. The formula for converting Nm to lb/ft is as follows:

The torque required to overtighten a screw may be converted to lb/ft using this formula:

To summarize, the amount of torque required to overtighten a screw is often 20 to 30% more than the recommended torque for the individual screw and material. This may be stated as a range of 12 to 15 Nm in Nm or a range of 8.850743638 to 11.06372089 lb/ft in pounds/ft. To avoid harming the screw and surrounding material, it is critical to follow the manufacturer's instructions for the right degree of torque and to use a torque wrench or other equipment to apply the correct amount of torque.

How Much Torque Are 50-Inch Pounds?

Torque is commonly given in newton meters (Nm) or pound-feet (lb/ft). The unit of 50-inch pounds is a torque unit expressed in pound-inches (lb/in), which is a typical imperial unit. The following is the connection between these units:

Using this conversion factor, 50 lb/in can be converted to lb/ft as follows:

50 lb/in = 4.16666666667 lb/ft

In addition, the relationship between lb/ft and Nm can be expressed by the following formula:

Using this formula, 50 lb/in can be converted to Nm as follows:

Taking the above calculation into consideration 50 lb/in is quite the same as “finger-tight” torque. It is sufficient to perform minor tasks without tools, but others may need a wrench or machine aid.

What Torque Is Good For Impact?

The amount of torque required for impact applications is determined by the task at hand and the materials being dealt with. Impact applications, in general, need more torque than non-impact applications because they entail the use of great force to loosen or tighten bolts or other fasteners.

Using an impact driver to drive screws or drill holes in wood or other materials is an example of an impact application. This tool is likewise intended to provide high amounts of torque in short bursts, often in the 60 to 120 Nm range.

Torque can also be stated in pound-feet (lb/ft) and Nm. The formula for converting Nm to lb/ft is as follows:

1 Nm equals 0.737562149 lb/ft

The torque range generally required for impact applications may be converted to lb/ft using this formula:

In summary, impact applications normally demand more torque than non-impact applications, and the required degree of torque is determined by the task at hand and the materials being dealt with. Impact wrenches and impact drivers are two examples of instruments intended to provide high amounts of torque in brief bursts, often in the 150 to 200 Nm range for impact wrenches and 60 to 120 Nm range for impact drivers. These ranges are comparable in pound-feet to 110.6372089 to 147.50281187 lb/ft and 44.25177398 to 88.50354795 lb/ft, respectively.

How Do You Tell If A Bolt Is Over-Torqued?

Over-torquing a bolt is when you apply too much torque during the tightening process, which can cause damage or failure to the bolt and its surrounding components. There are various indicators that a bolt has been over-torqued:

Visual inspection of over-torqued bolts:

Over-torqued bolts may seem strained or deformed. The threads may also be damaged or stripped, making removal of the bolt difficult.

Torque Measuring:

Torque wrenches and other tools can measure the torque exerted on a bolt. The bolt may be over-torqued if the applied torque exceeds the acceptable value.

Fatigue testing:

Over-torquing a bolt can induce metal fatigue, leading to splitting or breakage. This can be identified visually or by testing the bolt with appropriate equipment.

as we know,

1 Nm equals 0.737562149 lb/ft

For example, if the recommended torque for a bolt is 25 Nm, the following formula may be used to convert this to lb/ft:

25 Nm is equal to 18.43903523 lb/ft.

To summarize, there are numerous techniques to determine if a bolt has been over-torqued, including visual examination, torque measurement, and fatigue testing. When tightening bolts, it is critical to utilize the optimum degree of torque to ensure they are secure but not over-torqued. The suggested torque values for a certain bolt are normally provided in the manufacturer's instructions or may be found in reference sources such as the Society of Automotive Engineers' Torque Specifications Chart (SAE).

Posted 1 year ago by Admin

Comments

Recent Posts

Categories

- Length Conversions

- Year Calculation

- Financial Calculations

- Time Managment

- Mathmatics

- Weight

- Age Calculation

- Area Conversions

- Cooking Conversions

- Force

- Energy Conversion

- Frequency Conversion

- Pressure Conversion

- Volume Conversion

- Distance Measurements

- Health and Fitness

- Text Conversion

- Number Conversion

- Speed Conversion

- Temperature Conversion

- Electric Conversion

- Other

Related blogs

- Best Torque Wrench for Gunsmithing in 2023

- Torque It Up: How to Use a Torque Wrench and Which Ones to Buy

- How to easily convert newtons to kilograms

- Importance Of Foot-Pound (ft-lbs) To Inch-Pound (in-lbs) Conversion In Industrial Manufacturing

- Inch-Pound (in-lbs) To Foot-Pound (ft-lbs) Conversion: A Comprehensive Guide For Bike Maintenance

- How Torque And Wheels Affect Your Car’s Performance

Add a comment